We talk a ton about the good ol’ humidor box here at Case Elegance, but very rarely have we discussed its grandfather: the cigar box.

From handmade guitars and purses to jewelry boxes and treasure chests for pirate booty, the many uses we find for a cigar box are both widespread and creative.

Yet as diverse, artistic, and useful as they might be, few people know how the cigar box came into existence or the inner workings of this often-overlooked engineering feat.

It’s time we gave the cigar box some much-needed love, because if it were not for its invention, who knows what we’d be tossing our stogies in to keep them fresh.

Within the following four sections, we will investigate the reasoning behind the creation of the cigar box and its earlier incarnations. We will also discuss construction and materials used to form these handbuilt boxes, as well as what to look for in a cigar box if you plan on stashing some stogies inside.

Cigar Crates, Taxes, and Brilliant Banking Schemes: How the Cigar Box Was Born

Despite having been a huge part of North, Central, and South American indigenous tribal culture for centuries on end, the mass production of cigars never occurred until Europeans industrialized the process in the 18th century.

As tobacco transitioned from being a product that was only obtainable by wealthy Spanish aristocrats to a weekly expense for the middle-class, both production and demand increased exponentially. By the time the working class got hold of affordable cigars, the tobacco product was being shipped to a plethora of European countries and up and down the eastern United States.

Prior to the advent of the cigar box, cigars were typically transported in massive bulk shipments. Stogies were packed into all manner of container, with the contents of larger crates containing numbers in the thousands. This shipping solution saved both material cost and precious packing time and allowed the buyer or importer to divy-up the contents as they saw fit upon receiving the shipment.

Remember all those wooden barrels filled with cigars in old-timey cartoons? That wasn’t just some gimmicky prop idea put together by the storyboard department over at Warner Brothers one afternoon. Wooden barrels of cigars were indeed a thing back in the day. Thankfully the whole 55-gallon drum of cigars thing never stuck, giving way to far better forms of cigar humidor.

Uncle Sam and the I.R.S.

As with any consumable product, tobacco’s popularity eventually led to the U.S. government imposing a taxation system on the nicotine-rich plant. Up until the Civil War era, cigars were not regulated upon port entry or thereafter for that matter.

Part of this was due to cigars being packaged in such large quantities. The act of inspecting and taxing humongous crates of cigars was both time-consuming and difficult for federal officials. Looking to easily and effectively monitor, control, and tax the booming cigar business, President Abraham Lincoln cajoled the United States Congress into rectifying The Revenue Act of 1864, all in the hopes of controlling the number of cigars per package.

By 1865 the updated federal law decreed that all cigars must be sold in boxes containing 25, 50, 100, or 250 cigars. This law would later be amended to include smaller quantities of boutique cigars and cigarillos, both of which would also be inspected and stamped for taxation upon importation. This would ultimately lead to more stringent state-based tobacco tax legislation (on top of the already hefty federal tax) which would in turn spawn the birth of the Bureau of Alcohol, Tobacco, Firearms and Explosives (A.T.F.).

Box It Like It’s Hot

Not wanting to miss out on this massive moneymaker, Cuban cigar manufacturers and importers quickly switched tactics to meet this distribution and packaging law, with the Upmann brothers over at the H. Upmann cigar brand being the first to make a move.

As the tale goes, the H. Upmann brand was packaging cigars in smaller cedar boxes long before Congress put The Revenue Act of 1864 into play. As a banker specializing in the Cuban tobacco import/export business, H. Upmann founding president Hermann Dietrich Upmann was quite familiar with the importance of presentation.

For years the enterprising entrepreneur had been packaging some of the best cigars Cuba had to offer in small, Spanish cedar-clad boxes. Used primarily as a form of currying the favor of potential investors and powerful connections within the United States, these miniature cigar shipments doubled as a form of enticing potential bank customers.

Each box came adorned with the Upmann banking brand name, with a variety of cigars from various manufacturers being stuffed within. Naturally, this led to the development of the H. Upmann cigar brand in 1844, which would ultimately use its original gift box idea to quickly and easily transition to this more limited form of product packaging.

Tobacco Nerd Note: The biggest names in the cigar biz tend to have their own cigar box manufacturing facilities on-premise, or at least somewhere nearby. There, woodworkers and artisans work alongside the brand’s design and marketing team to make sure that the master blender on the other end of the operation receives a box befitting the product they have worked so hard on producing from scratch.

Materials Used To Make a Cigar Box

As the bean counters, shipping departments, and the cigar-smoking public let out a unified cry of anguish over the higher prices and logistical headaches associated with The Revenue Act of 1864, a select few individuals squealed in glee. This was the moment that cigar marketing specialists, salesmen, and artisans had been waiting for: an opportunity to turn cigar containers into beautiful marketing billboards.

With the demise of the 2,500+ count cigar crate (and barrel) came a swath of colorful, ornately decorated smaller cigar boxes. Following H. Upmann’s lead, and adhering to the inevitable fact that bugs despise Spanish cedar, cigar manufacturers began contracting out the production and illustration of their government mandated cigar boxes.

Although the larger boxes remained quite crude in design, as they very rarely were put on display due to their hulking size, the smaller 25-50 count boxes served as a brilliant form of marketing. Standing side-by-side, row upon row of rectangular, incredibly detailed cigar boxes vied for attention at countless saloons, hardware stores, provisions outposts, and smoke shops across America.

Despite being constructed almost entirely from cardboard, thin wood, and paper, even the most base-born cigar boxes were often adorned with beautiful artistic influence. From gold foil and finely tipped calligraphy, to richly colored print work and emboldened name branding, the art of turning a plain old slab of Spanish cedar into a reusable piece of marketing paid off in spades for cigar makers.

Naturally, woods like Yellow Poplar and Eucalyptus were also put into effect due to affordability and availability, which in turn led to the use of far more decadent hardwoods. As time went on, limited-release cigars for the upper class began to be packaged in heavily-clad and oiled wooden cigar boxes. Relying upon fine humidor wood, many of these high-end cigar boxes relied upon White Oak, Mahogany, Elm, Circassia, Rosewood, Basswood, and Cherry for their construction.

Recently, the use of acetate composites, polymers, and even real carbon fiber have been utilized as cigar box construction materials. May they be flashy, swanky, minimalistic, artistic, rustic, unassuming, or some blend of the above, the materials that make cigar boxes possible are just as diverse as the cigars we smoke.

Cigar Box Designs: Styles for Miles

Categorizing cigar boxes is about as cut-and-dry as explaining automobile trim levels. Just when you think you’ve got them all down, a sub-model spin-off emerges.

So for the sake of simplicity, we will categorize the majority of the cigars you see on the shelf into the following categories:

Hinge-Lid Cigar Box

The most basic of all cigar boxes. Often constructed with glue and paper in place of hinges to cut down on cost, and constructed from thin Spanish cedar and/or cardboard. Sizes typically are built for lower content, with anywhere from 5-50 sticks being stuffed inside at one time.

Slide-Lid Box

Engineered for cigars with larger ring gauges (think La Aroma de Cuba and La Gloria Cubana), as well as slightly higher count boxes ranging anywhere from 25-to-100 cigars. Often made from thinner grades of spanish cedar to reduce weight and allow easier lid sliding action.

The Flat Top/13-Topper Box

This cigar box sports two internal layers, with an even dozen stogies on the underside and 13 smokes on top. A pre-formed rectangular box made from wood or cardboard that is the same size as the cigars within the box is typically affixed to one end of the lower row to support the additional cigar sitting on top.

Box-Pressed Cigars Boxes

Due to their square shape, box-pressed cigars can be neatly stacked atop one another in equal amounts. The construction of these boxes can be of any form, but the traditional rectangular shape is most common.

8-9-8 Box

The 8-9-8 cigar box is a bit of an oddball, in that it typically is made from thicker Spanish cedar, and features either sharp, hexagonal corners or round-siding. While single-tier, non-deviated options are out there, many cigar brands prefer to add a thin layer of Spanish cedar between each row of stogies. Together, these three separate layers form a cigar box that is filled with eight sticks on top, nine in the middle, and eight along the bottom row.

Tobacco Nerd Note: As with any form of marketing and packaging, the design process associated with producing a new cigar box from thin air requires a ton of time, money, energy, creativity, brainstorming, and rejection. Imagine the team from Mad Men, but they all speak Spanish fluently and prefer to smoke stogies.

Repurposing a Cigar Box as a Humidor

What happens to these spent tobacco containers once they have been exhausted of their precious smokeable resources is anyone’s guess. Cigar box guitars, jewelry boxes, a stash box for your hippie uncle’s homegrown “herbal remedies,” and handmade purses are but a few of the many uses for retired cigar boxes.

Although brand identity and eye-catching marketing methods are the top two purposes of a cigar box (following the need to keep a specified stick count intact), the second half of a cigar box’s life does occasionally mirror its original occupation.

Those who decide to extend the service life of a cigar box by repurposing it as a humidor do so for good reason. Oftentimes the same grade of humidor wood found in large cabinet-style humidors can be found in higher-end cigar boxes.

Forget those flimsy, paper and glue-hinged cigar boxes. We’re talking “Grade-A” craftsmanship here, people. The type of box that is so ornate that it causes you to pause in the walk-in humidor and say, “Well damn! They pulled out all the stops with that cigar box.”

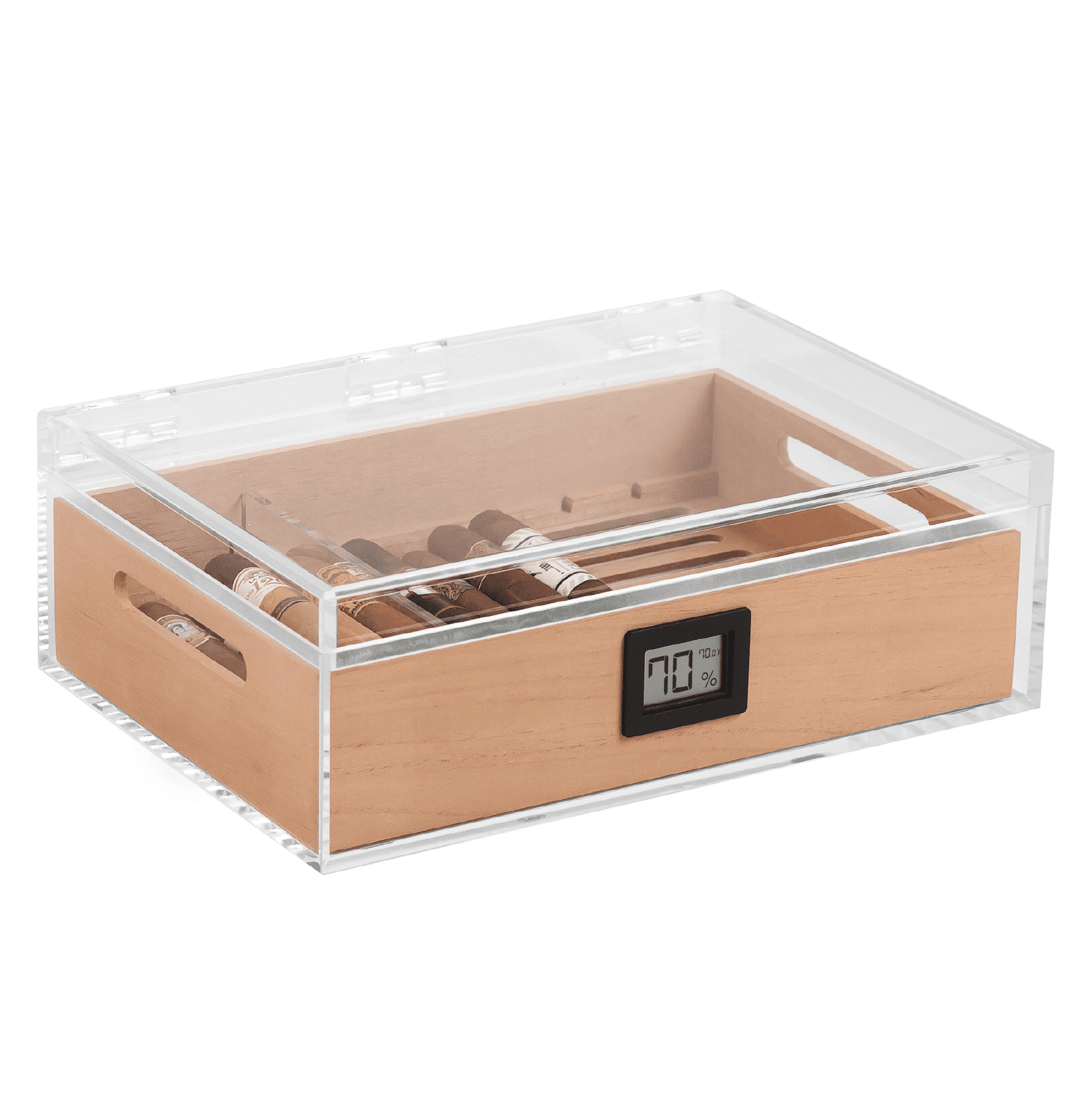

That said, if you are considering turning an old cigar box into a humidor, you don’t have to go for the slickest slab of humidor wood on the shelf either. In the world of cigar humidors, function far outweighs form. Understanding the purpose of a cigar humidor box requires recognizing that it is not just a secure home for our precious cigar collections, but a means of maintaining proper humidor humidity levels and keeping contaminants at bay.

Here are three key features and attributes to look for in a potential cigar box humidor:

- A super-tight seal (a dollar bill stuffed inside the closed lid should be difficult to pull out)

- Sturdy hinges (this will help guarantee that the lid aligns with the coping of the box itself when closed and guarantee decades of safe usage)

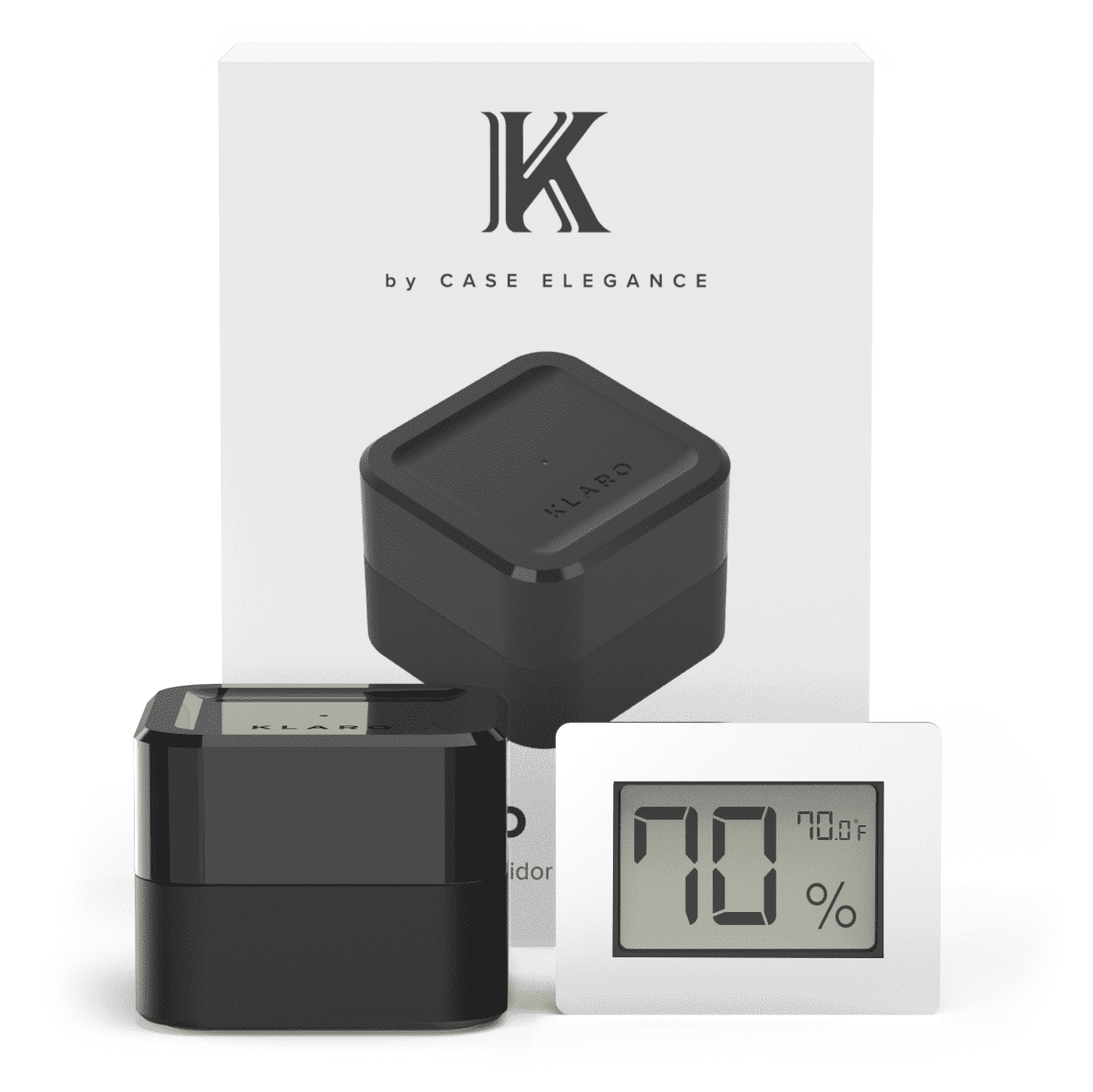

- Multiple storage tiers (you’ve got to put your calibrated hygrometer and humidor packs somewhere, so they might as well have their own dedicated space)

Tobacco Nerd Note: A cigar box doesn’t have to be made from wood to be of high quality. Sure, Spanish cedar does smell sensational and does absorb and expel moisture like a champ, but that doesn’t mean it’s the only high-grade material on the block. Many of the nicest cigar boxes on the shelf are often constructed from acetate, leather, or some form of mixed media.

Parting Puffs

Unless you are in the tobacco business, cigar culture is all about indulgences and relaxation. Even before a cigar is lit with a searing torch lighter, there is a pleasure to be had at every stage, including the shopping and purchasing process. From mild to wild, cigar boxes can be obtained in an array that is as diverse as the cigar types that grace their confines.

What began as a mandated form of monitoring and taxing tobacco products, evolved into a stunning way of advertising cigars, and making the cigar buying experience all the more memorable.

Equally ingenious is the methodology used to craft these stogie storage containers. From traditional Spanish cedar construction to opulently oiled mahogany and rosewood inlays lined with crushed velvet, to slick synthetic resin flow-formed cases with tanned leather inserts, cigar box options abound.