We talk a lot about the importance of owning a quality humidor, best practices for maintaining your humidor’s performance, and how the components of your humidor ought to function. And there’s good reason for that: Each Klaro humidor was created to remedy the problems cigar owners face when it comes to protecting their cigars. As cigar smokers and enthusiasts ourselves, we design humidors to meet our own high expectations.

In designing Klaro humidors, we’ve spent countless hours imagining, planning, and testing every facet of the humidor so that you could own an affordable, quality product that you can be confident will perform year after year.

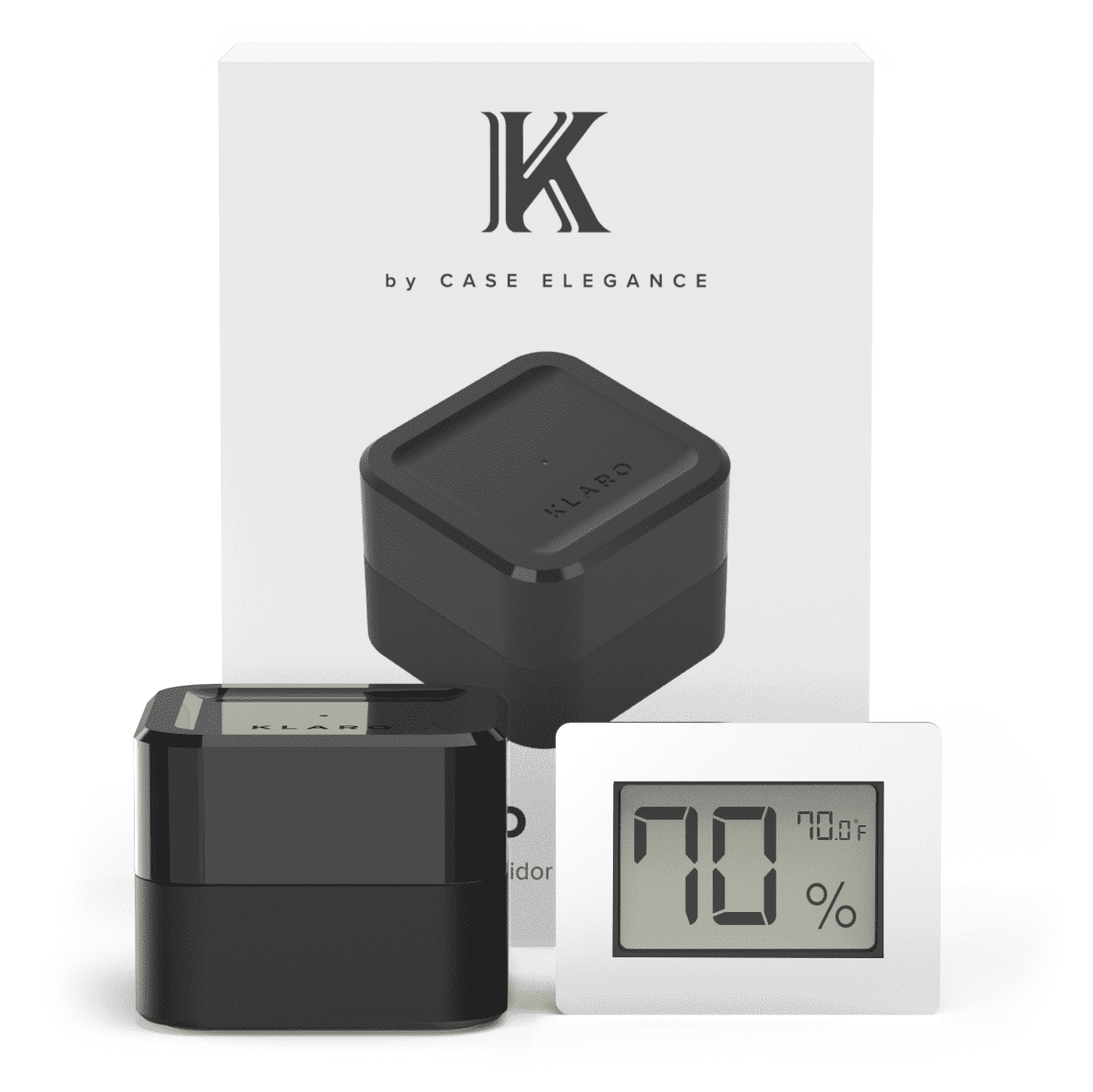

With each new humidor release from Klaro, there is a backstory. From identifying a market need to initial designs to at-home testing conducted by our crew, each humidor in our line-up represents a substantial pass/fail process before it ever reaches the market. Today we take a look behind the scenes at the Case Elegance lab to see some of what goes on when we imagine, create, and release a new humidor.

Designing a Humidor: The Early Stages

Peruse the selection of Klaro humidors and you’ll see iterations of humidors that could appeal to different types of cigar collectors and enthusiasts, ranging from the large-capacity Glass Top Octodor to a tribute to the armed forces with the Military Glass Top humidor. There’s a style, purpose, and backstory to each model.

We spoke with Ian Bennett, the Product Lead at Case Elegance, responsible for the design of all Klaro humidors. For him, designing a humidor starts with finding a niche to expand upon within the Klaro line-up.

As a cigar geek himself, he has first-hand experience with the challenges, needs, and interests of cigar collectors, and his humidor design process begins when he identifies a problem to be solved, a need to be met, or something to be improved upon. That’s where such innovations as the Hydro System originated–from the lack of an efficient humidor humidifier in the market.

For Bennett, the impetus to create a different humidor model can come from a functional issue like capacity–how many cigars a unit can hold–or from an aesthetic concern–modern versus traditional, for example. From there, he sketches designs by hand, what he believes is the “bread and butter” of design.

“I might sketch thirty different versions of one humidor and only select two or three to take to the next phase of rendering,” he said, a process that happens through computer-aided design programs. “I get an idea of what I like, what I don’t like, and play with materials and shapes.”

Bennett notes that sketches and early designs are great for ideation, but the design changes throughout the process based on the reality of certain constraints, like materials, cost, and functionality. “A good designer’s skill is making tough decisions on where to cut and what to keep based on time and cost.”

Designing through Engineering

The second phase of humidor design relies on an engineering mind frame, Bennett says. “You have to converge, make tough decisions, and make sure it can be built, and that’s a totally different side.”

While each of the Klaro humidors clearly has a distinct aesthetic design, there’s always a balance when it comes to functionality, and the aesthetic has to follow suit to the humidor’s performance.

Take the stark aesthetic difference between the Kobi and the Belmont Glass Top humidor–both recent releases from Klaro. These two humidors, while very different in appearance and aesthetic, were adapted from tried-and-true functional features of Klaro humidors–like thick cedar inlays and gasket-sealed hygrometers in different locations.

Bennett uses an engineering framework to approach new designs: start with the constraints, and then create solutions based on the problems you identify as you design.

“We focus on products that solve problems. There are very few brands built around aesthetics alone.”

To showcase this, Bennett cites the Hydro System and their approach to digital hygrometers as examples of solving problems through design.

Hydro System

The origin of the Klaro Hydro System was based on frustration with the market’s products for humidor humidification. “I always hated this awkward puck; it took up too much cigar space, and it also didn’t work.”

Bennett and the team realized a lot of humidors also relied on a somewhat-questionable sponge material that also proved to foster mold growth. That’s when they had the idea for edge-to-edge coverage with a tray that allowed for humidification to extend across the storage surface area. And once they had proved the success of the Hydro Tray, developing their own solution was the likely next step.

“We developed a crystal, but that wasn’t enough, and we needed to dial in the humidor solution ratio,” Bennett said. “Everyone does 50/50. Well, that doesn’t work in Nevada. You have to do a different ratio. So we came out with a winter mix and a dry-climate mix. When humidity tanks in the winter, you now have a different type of solution that really helps with that fluctuation. It has a faster dispersion rate than a more alcohol-prone solution,” he continued.

Hygrometers

The team learned early on that, when it came to measuring humidor humidity, analog hygrometers were just about useless in most humidors. Even with those that claimed accuracy, you could quickly test them by blowing air at the screen, and the number would fluctuate.

“The problem is people are buying a $30 humidor on Amazon and think they’re working, but they’re not, and their hygrometer is lying to them,” Bennett said. Analog hygrometers are factory-calibrated, deceiving customers who trust readings from a sub-par measurement tool. And the problem extends to cheap humidor digital hygrometers, too.

Their initial solution for Klaro was to add gasket seals to their digital hygrometer, which helped. But they still weren’t getting a completely accurate reading of the internal humidor. So they extended the sensor further into the humidor box, better adapting it to take an accurate reading, which worked. They’ve since applied this extended sensor to all their digital hygrometer humidors.

“You have these core problems that exist in all humidors. Well, you need to build a framework that can be suitable for all humidors. You have this Hydro System and humidor solution, so now it’s my job to think on the other side of my brain and come up with something that’s beautiful, too.”

The aesthetic design happens in tandem with the functionality of the humidors. The results speak for themselves.

Tried and Tested

Once a prototype has been built, the humidor gets put to the test. And it’s a thorough test: the Klaro team puts those prototypes through the gauntlet to see how they come out the other side. They conduct a pretty extensive sample review process, which involves two or three samples in a variety of situations, including climate testing at a range of different outside humidity levels. This rigorous testing is necessary before a production run to ensure they stand behind the final product.

“I personally test everything we make,” Bennett said.

Next in the works? Bennett shared that he’s working on a new humidification system that builds on some of the groundwork laid with the Hydro System. Think of that same quality of humidor humidification, just on a smaller scale. But that, for now, is all Bennett is willing to share. To keep updated with the latest products and releases from Klaro humidors and Case Elegance, sign up for the newsletter and follow along on the blog to learn more.